[

{

"name": "500x250 Ad",

"insertPoint": "5",

"component": "15667920",

"parentWrapperClass": "",

"requiredCountToDisplay": "1"

}

]

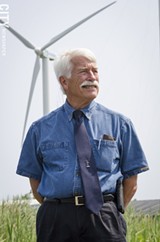

Bob Bechtold built a successful manufacturing company by embracing new technology, not treating it as a threat.

Bechtold founded Harbec, Inc., almost 40 years ago in the Wayne County town of Ontario as an all-purpose machine shop. Computerized machine tools were just starting to make their way to shop floors, and some in the toolmaking and machining industries worried that the technology would supplant highly skilled workers.

Bechtold says he believed that computers would be the best tool that toolmakers ever had.

"And so I began wherever I could to change Harbec general purpose machine shop into Harbec, utilizer of technologies and opportunities to forge new business opportunities," he says.

And since the late 1990's, Bechtold has taken a similar approach toward his company's environmental footprint. It's important for Harbec, and for other companies, to take responsibility for their environmental impacts, he says. So Harbec now includes environmental considerations in its decision-making. And it looks to technology to lessen those impacts.

As a result, Bechtold says, Harbec is more competitive and has improved its financial performance.

"It really has become an integral part of the company that I think will continue after I fade into the sunset," he says.

Harbec employs more than 140 people at its facility on Route 104. It produces incredibly precise plastic and metal components for companies in a variety of industries. Like most manufacturing facilities, its operations are energy intensive. Yet last year, its energy use was carbon-neutral.

Many companies are taking steps to reduce their environmental impacts. Apple and Google attracted a lot of attention for their efforts toward carbon neutrality. And locally, Diamond Packaging purchases wind power to cover all of its electricity needs, for example.

But companies' claims of carbon neutrality are frequently met — and rightly so — with skepticism, often because they rely on purchased emissions offsets. While Harbec makes some use of offsets, its emissions reductions have largely resulted from energy efficiency projects and use of renewable energy sources.

Harbec has made years' worth of serious, deliberate efforts to reduce its environmental impact. And government officials and local environmentalists periodically single the company out for those efforts, citing it as an example for other mainstream companies to follow.

The push started with the installation of an on-site combined heat and power system, which was essentially a large energy efficiency project. The system's generators burn natural gas to create electricity, and the hot steam also produced during that process is used for heating and air conditioning.

Over the next few years, Harbec installed two wind turbines, which now generate about 60 percent of the company's electricity. It buys another 20 percent of its electric from the grid, though from carbon-free sources. Between the turbines and the purchased power, Bechtold says, the company avoided 1,632 metric tons worth of carbon emissions last year.

Harbec's combined heat and power system provides the remaining 20 percent of the company's electricity, Bechtold says. Since the system burns fossil fuels, however, it does produce carbon emissions. Last year, the company purchased 670 tons — 608 metric tons — worth of carbon offsets to cover the emissions as well as the emissions of all company vehicles, Bechtold says.

Now, Harbec is adding water conservation to the mix. The company is participating in a new extension of the US Department of Energy's Better Buildings Challenge, which emphasizes reducing energy use by reducing water consumption. Harbec plans to do that by recycling water and reusing rainwater — relying on municipal fresh water only for drinking and hand-washing.

In a recent interview, Bechtold talked about his company's energy and environmental initiatives. The following is an edited version of that discussion.

CITY: When did you begin incorporating environmental principles into the company?

Bechtold: In the late '90's. I had been very interested in it and working successfully with it at home. I had my first wind turbine at home in 1980, and a lot of things like that I was learning about, experimenting with, and got a level of confidence that eventually I began to try and bring it into the company.

And by the late '90's, the company was pretty substantial and good revenue flow and all that, so I thought it had potential to be just as dynamic for a manufacturing company as it was for our home. And that's where it began.

What was the company's first step?

The first thing I thought would work was a wind turbine. The problem was, back then, it was impossible to get funding for a wind turbine. At the same time, we were having an issue with heat in our shop. There was no relief. You could put fans up, but you were just blowing hot air.

And so I began to look into ways of air conditioning an injection molding plant. To put it into perspective, the molding room is 9,000 square feet and there are 25 injection molding machines in it. So the task is comparable to taking a gymnasium and putting 25 industrial pizza ovens in the gymnasium, turning them all on high, and running them 24 hours a day.

I began studying what the Europeans were doing with energy and efficiencies and learned about combined heat and power. With only using the waste heat — the thermal opportunity — of on-site power generation, we're air conditioning [the shop] with almost no new energy.

All of the things that we do, rest assured that I can show lots of detail about how economically advantageous they are to this business. When in early days I was beating my head against the wall trying to sell this, to get a bank to provide the lending, I realized one day that I was branding myself as a burned-out hippie because I was talking green stuff. So I stopped, came back in and rethought the whole story, and then went from that day forward always economic.

Once I did that, I went back out and talked to the bank about economic opportunities and doing combined heat and power and a wind turbine together. I was able to bank it. And ever since then, it's been always the lead. I start out by showing whoever it is how the economic advantages happen, then if they're interested and they want to learn about it, I can show them how much carbon is saved and everything.

I believe the only way, especially in business, we're ever going to make an environmental improvement is if we can prove that it's economically advantageous.

Does technology help your company control its energy use?

There's an example — a new area, a new potential — it's an alternative to an existing die-casting technology everybody knows very well. But in potential it does a more accurate part with about one-one-hundredth as much energy.

[It's] because we're literally able to go from a pellet to an injection molded part in two to four minutes, versus die casting which is a constant flow of energy.

Do you think business has a responsibility to lead on environmental and sustainability issues? And how does it do that?

An industry, a factory, especially manufacturing companies, we have big, huge footprints. So if anyone should start to be responsible for the impact, it's the biggest impacters. And that's us. And so that's why we are the kind of company we are.

I started out wanting to make my little impact on my home, and then I thought if I could do it there, why couldn't I do it in the factory? And so I started to figure out ways to do that.

Today, we have succeeded and we are carbon neutral and that's just this year. And by the end of 2015, early 2016, we will be also water neutral. What does that mean? It means that we take all of the responsibility for all of the carbon that is a result of our manufacturing and all of the water consumption that is the result of our manufacturing.

If you look at what Walmart is doing, by the end of 2015, every package on Walmart's shelves is going to have a new label on it. And the label is going to be your impact label: how much was the result of this pair of blue jeans or this TV set or whatever the device is, in environmental impact? They've been working on it since 2010; they've put millions of dollars into it, so I don't think it's going to go away.

If I tell you the real reason — because of my children and grandchildren and great-grandchildren — who cares except for me?

Speaking of...

-

Bausch + Lomb marks 50th anniversary of the soft contact lens

Mar 26, 2021 -

Earth Day: Events to celebrate home – from home

Apr 22, 2020 -

Monroe County, Rochester won’t tax paper bags

Jan 6, 2020 - More »

Latest in News

More by Jeremy Moule

-

ROCHESTER TEN

ANNETTE RAMOSAug 1, 2023 - More »